Today the team began boring the well hole through the Ross Ice Shelf. They’re using water from snow melted in the flubbers, circulated through our six boilers to reach a temperature of 75°C, passed down a hose and through a hot water drill nozzle, which is slowly lowered to melt a hole through the ice.

They’ll keep melting until they get below sea level – around 80m below the drill tent – and then bore a well cavity, and lower in a pump.

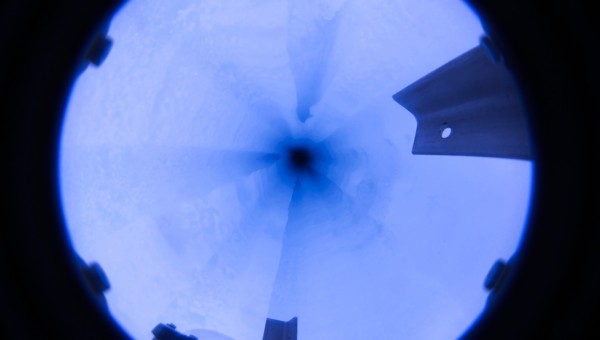

The first pass of the hot water drill uses a spray head to make the initial hole, followed by a reamer to widen it, and then the ‘Christmas Tree’ attachment to make the cavity.

Once the well pump is in place, and circulation established, they’ll have an endless supply of water for drilling our main hole, all the way through the 580m of the ice shelf.

The whole process through to well pump installation takes around 12 hours – time for a crossword or two!